How to Choose Your Perfect Scuba Regulator

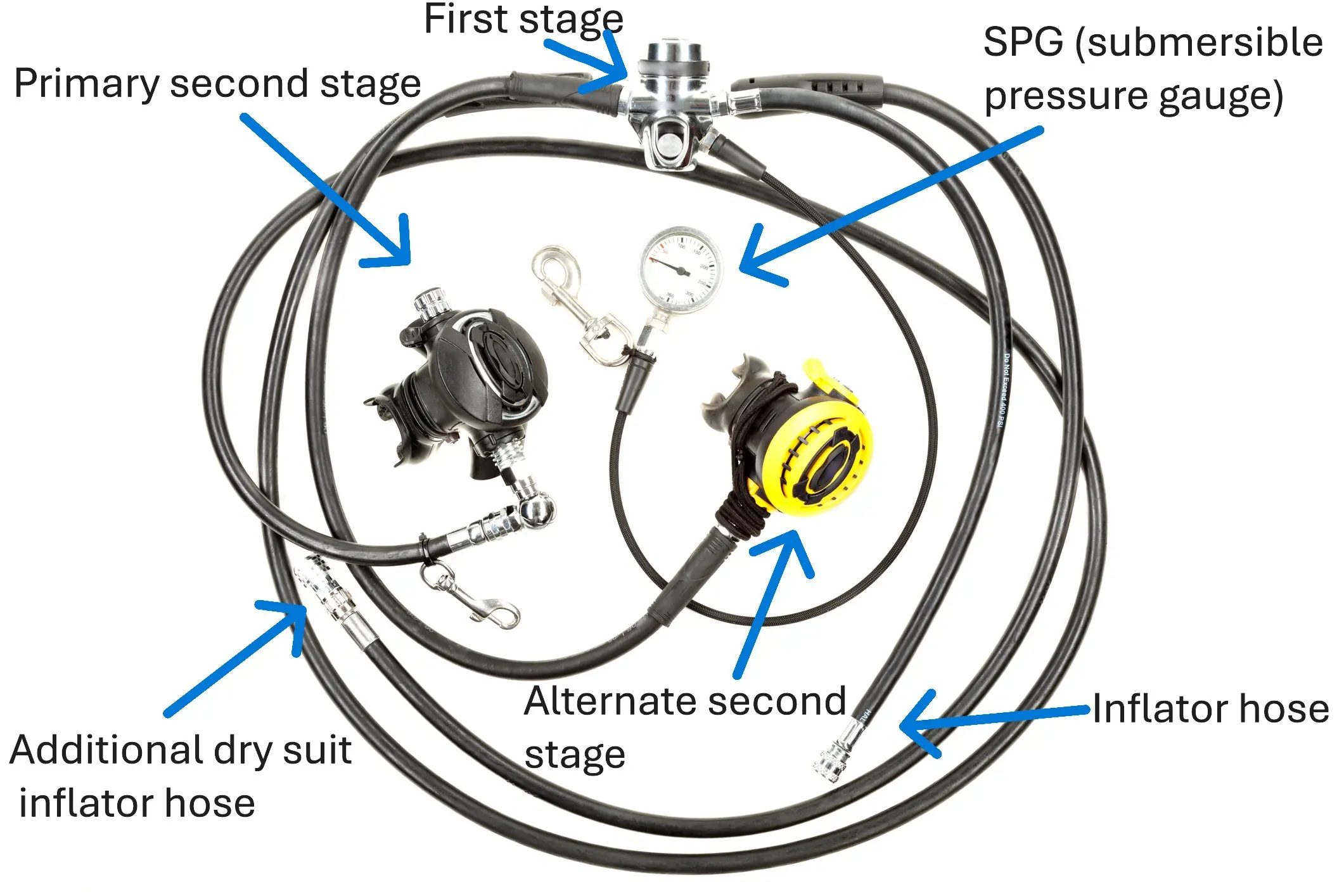

Scuba regulators form the foundation of the scuba systems, linking everything together with you. They consist of two parts: the first stage and second stage. The first stage attaches onto your scuba tank and has connection ports holes. There are usually five or more, at least one high pressure port and four low pressure ports. For most scuba kits, these hoses are a low pressure inflator hose (LPI), submersible pressure gauge (SPG) and two second stages: your primary second stage and alternate second stage called an octopus.

During all PADI courses (besides some TecRec courses), you will use “open circuit” scuba regulators. This means that when you exhale, the air you breathe out is released out of the scuba system. This can be seen in the form of bubbles coming out underwater. Scuba regulators are also known as demand valves or demand regulators as they supply air “on demand” as you breathe in, so air isn’t continuously flowing. Ultimately the scuba regulator provides you air from your scuba tank for you to breathe safely underwater.

Why Do We Need Scuba Regulators?

As mentioned, the scuba regulator delivers air from the tank. But why can’t we breathe from an open hose connected between the tank and our mouth? There are two reasons for this:

- 1

The air pressure that is released from the scuba tank is high. In a full tank, this is 180-220 bar or around 3000 psi which is even more than the pressure delivered in a standard pressure washer. The first stage of the scuba regulator is designed to lower this high pressure to what we call intermediate pressure. This is around 8-10 bar or 120-150psi above ambient pressure. The second stage then delivers air to your mouth at a safe pressure, similar to the pressure surrounding you.

- 2

As you go deeper, water puts more pressure on the body. Our respiratory system works only when there is a pressure difference of less than 0.14atm/bar between the pressure of air that comes into your lungs and the pressure surrounding you. At 3 metres, this difference is already 0.3atm/bar. Therefore the scuba regulator is designed to reduce this difference so that the air you breathe is similar to water pressure at the depth you are at.

Even though a scuba regulator serves a very simple purpose, investing in the right regulator will provide the best experience for the type of diving you do. It’ll also be reliable, require minimal servicing and overall feel more comfortable. Each part (first stage and second stage) can either be sold separately or as a set with the additional hoses (SPG and inflator hose). So there are many ways to customise your scuba regulator to best suit you.

Features to Consider in a Scuba Regulator: Second Stage

Configuration

Second stages are configured with a mouthpiece, a diaphragm controlled demand valve and an exhaust diaphragm. A standard second stage will have the diaphragm at the front (also identified as the purge button) and exhausts at the back. The demand valve operates when a diver inhales. This pushes the diaphragm onto a demand lever which opens up the valve and delivers air to the diver. On an exhale, air is released through the exhaust diaphragm in the form of bubbles to the side of the diver’s face. Demand valves are also downstream valves, meaning that air always flows from the tank towards the second stage, even when the second stage malfunctions.

Other configurations more uncommonly seen use something called a pilot valve. The smaller pilot valve opens the main valve offering a two stage system that offers greater airflow with less breathing effort. However they are much more complex to service and have a tendency to free flow. The diaphragm and purge button are located either on the side or bottom of the second stage.

When purchasing a pilot valve regulator, it is also important to ensure that it is fail-safe. This means that it has a downstream flow which opens the valve with the flow of air rather than upstream which opens against. Therefore when the regulator malfunctions, air continuously gets delivered (a freeflowing regulator) so you can still breathe from it to ascend safely to the surface. Definitely something to consider to promote your own safety.

Another feature in new higher end models are ‘balanced’ second stages. Unlike balancing the first stage, this doesn’t improve breathing performance but allows manufacturers to use premium materials which are more long-lasting and perform better.

External adjuster

In all second stages, you can change the tension of the valve making it easier/harder to open. Tuning it up makes the regulator easier to breathe from but more sensitive to free flow and detuning does the opposite. This can be adjusted internally by a technician but some second stages offer an external adjuster. This can be found as a knob on the side of the second stage which you can turn up or down. Having an external adjuster allows you to fine tune your own breathing resistance and ensures the tension of the valve remains optimal so that performance isn’t affected as your regulator ages.

Venturi assist switch

This is an adjustable switch, also located on the side of the second stage and helps to reduce breathing resistance by redirecting the air flow. When this is turned on, this switch uses something called the venturi effect which creates ‘low pressure assistance’ making inhalation more easier. This makes dives much more comfortable as breathing requires less effort.

There are many features to consider between different models and types, but this doesn’t need to complicate your decision. Overall, the main points you need to think about when choosing the right regulator for you are: